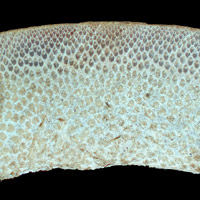

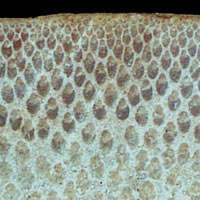

The 'Guadua', which was first identified as 'Bambusa guadua' by Humboldt and later defined by Kunth as genus 'Guadua' (including eight subspecies of 'Guadua angustifolia'), usually grows from sea level up to 2.000 m altitude in little woods along brooks, but also on meadows or sloping sites. Each stem grows out of a reticular root system, the rhizomes.