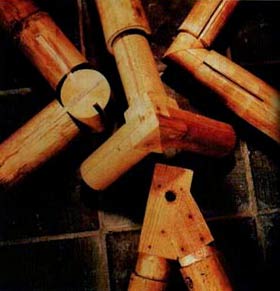

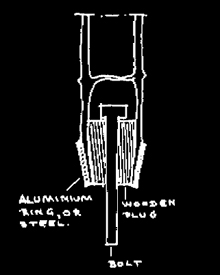

Already several architects and engineers occupied themselves with the development of a useful connection of bamboo tubes and presented many different solutions, reaching from simple lashing and glueing techniques over combined solutions to complex connections, for example, injecting concrete and transferring forces through screws and steel tabs.